If you’ve ever finished a busy week, looked at your sales numbers, and thought, “We should be making more than this,” welcome to the club.

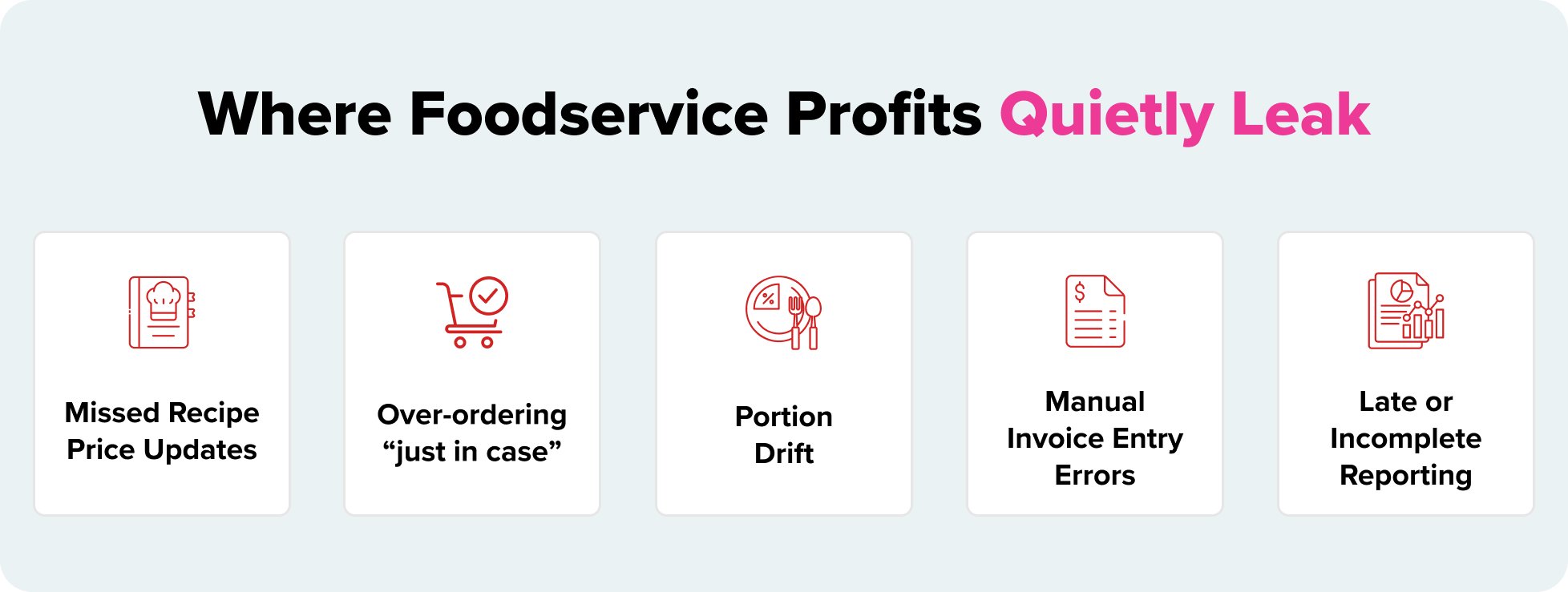

Foodservice margins don’t disappear in big dramatic losses — they quietly bleed out through small inefficiencies:

- A price tweak on chicken that never made it into your recipe costing

- Items being over-ordered “just to be safe”

- Menu portions drifting instead of staying tight

- Invoices coded by hand after a 10-hour shift

- Reports that come together too late to fix anything

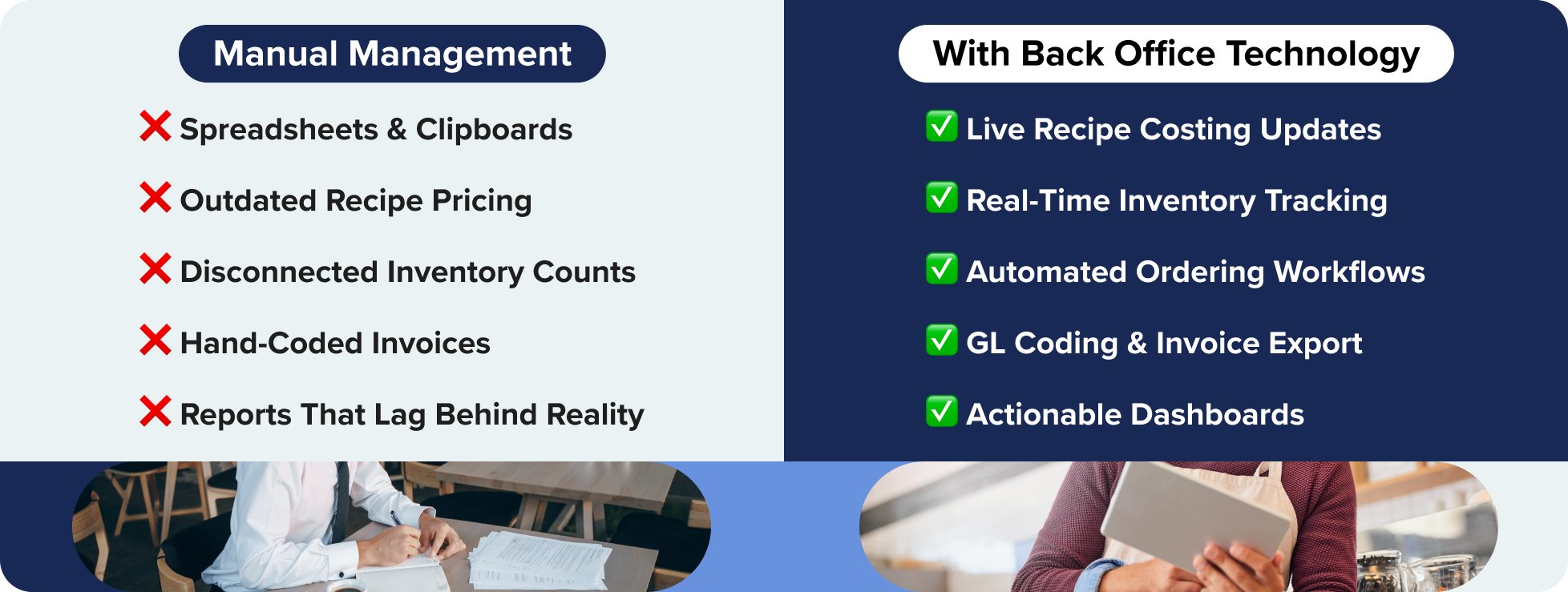

This is exactly why food cost management is no longer something operators can handle with clipboards, spreadsheets, or “gut feel.” Those tools only show you what already happened — not what’s happening right now.

Food cost management technology is what bridges that gap. It gives operators clear, real-time insight into where money is going, what’s changing under their feet, and how to take back control of margins before profit walks out the door.

Why Food Cost Management Feels Harder Than It Used to Be

Food pricing has never been stable — but the last few years changed the game. Ingredient volatility, freight fluctuations, labor shortages, packaging increases, and distributor price updates now happen faster and more frequently than most teams can track manually.

In 2023, 76% of operators reported higher food costs, and the pressure hasn’t exactly cooled off since. What’s changed isn’t just prices — it’s the speed of movement across the supply chain.

Most operators aren’t dealing with “bad decisions.” They’re dealing with late information:

- Recipes based on outdated ingredient pricing

- Inventory counts done after spoilage already happened

- Budget reviews that lag weeks behind real spending

- Invoice coding mistakes that don’t surface until monthly reconciliation

Without systems that connect purchasing, costing, inventory, and accounting data, operators are essentially managing blind spots instead of managing costs.

Where Technology Makes the Real Difference

Food cost management technology doesn’t just organize data — it replaces guesswork with precision. Buyers Edge Platform’s Back Office technology was built specifically for restaurant operations, not repurposed from retail or generic accounting software. It focuses on the daily workflows that directly determine margin performance.

Here’s how it solves four of the biggest food cost challenges operators face.

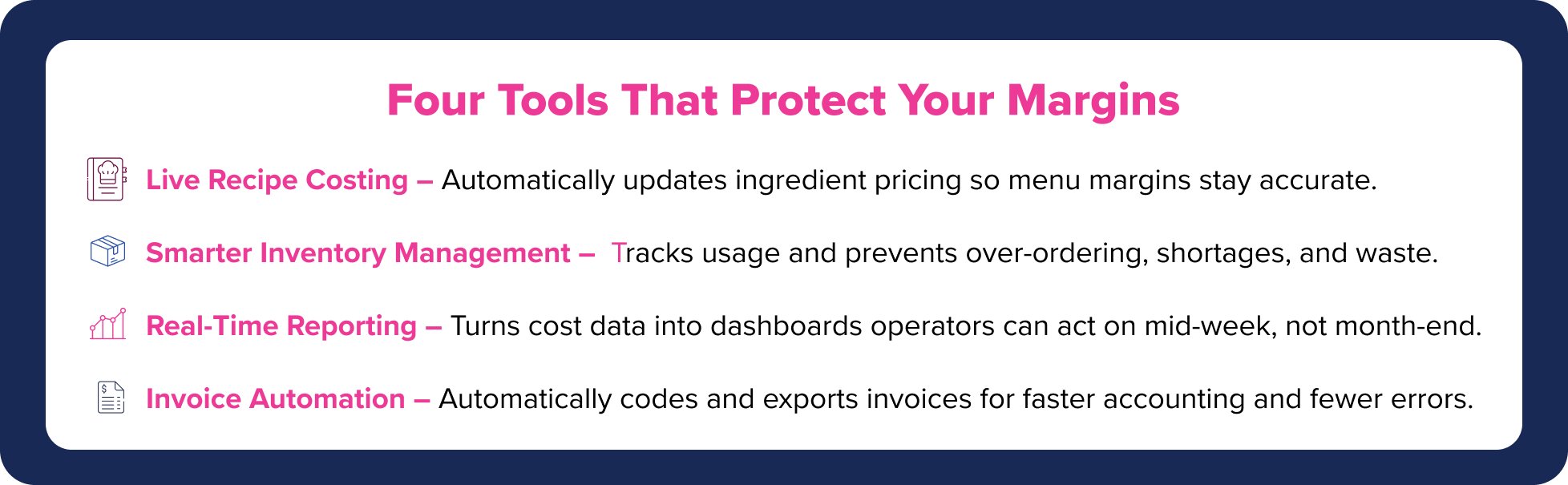

1. Recipe Costing That Stays Accurate — Automatically

Menu pricing doesn’t stay profitable when ingredient costs change. But manual recipe updates almost never keep pace with supplier pricing shifts.

Back Office automates recipe costing by connecting live product pricing directly into your recipes. When ingredient costs change, your recipes update with them — automatically.

What that means for operators:

- No more manually adjusting line items

- No more selling dishes below margin without realizing it

- Faster decisions on menu pricing adjustments

- Real visibility into which items are profitable — and which aren’t

It turns recipe costing into a living tool instead of a static spreadsheet that’s outdated the minute it’s saved.

2. Inventory and Ordering That Reduce Waste — Not Just Count It

Inventory is one of the biggest silent killers of profit. Over-ordering leads to spoilage. Under-ordering leads to last-minute purchases at higher prices or menu shortages.

Back Office makes managing inventory easier by digitizing counts, keeping track of how things are used, and predicting needs based on real data instead of gut feelings.

Operators get:

- Reordering that makes more sense based on how products are actually moving

- Less “panic buying” at higher prices

- Less waste and too much stock

- Better alignment between forecasting and prep volumes

Instead of being a chore that you do once a week, inventory becomes a tool for keeping costs down that works quietly in the background.

3. Reporting That Operators Can Actually Use

Reports are only useful if you can act on them while decisions still matter.

Back Office reporting turns raw cost data into straightforward dashboards showing:

- Food cost fluctuations

- Category-level spend trends

- Inventory valuation changes

- Vendor cost comparisons

- Recipe margin performance

This isn’t accounting for accounting’s sake — it’s operational intelligence.

Operators can spot:

- Which suppliers are drifting on pricing

- Where food cost creep starts showing up

- Menu items quietly losing profitability

- Spend outliers before they escalate

Instead of discovering issues at month-end, teams catch them mid-week — when changes can still protect margin.

4. GL Coding and Export That Ends Administrative Bottlenecks

Invoice coding is one of the most time-consuming tasks that managers don’t realize they do. Every week, hours are lost to entering data by hand, coding invoices incorrectly, and reconciling differences.

Back Office automatically codes GL and sends invoices straight to your accounting system in the right way every time.

The benefits:

- Fewer data entry errors

- Faster month-end closings

- Cleaner financial reporting

- Reduced accounting back-and-forth

Operators spend less time fixing coding mistakes and more time focused on food, people, and guests.

What “Effective” Food Cost Management Actually Looks Like

When food cost management technology is working the way it should, operators experience three major shifts:

1. Visibility replaces surprises

Price changes, margin erosion, and spend spikes no longer show up late, they’re visible while operators still have time to act.

2. Control replaces reaction

Menu pricing, purchasing decisions, and portion adjustments become proactive strategies instead of damage control.

3. Efficiency replaces administrative drag

Teams spend less time entering data and reconciling numbers, and more time improving operations and guest experience.

Profit protection shifts from “hoping the numbers work out” to knowing exactly how they perform.

The Future of Food Cost Management Technology

Foodservice technology is entering its smartest phase yet. Automation, advanced data integration, and predictive analytics are no longer reserved for large chains only — they’re becoming accessible to multi-unit and independent operators who need every margin advantage possible.

The future isn’t about replacing people with technology, it’s about supporting teams with systems that:

- Forecast ingredient needs more accurately

- Predict menu item profitability based on live market conditions

- Reduce data entry and reporting burdens

- Create connected operational intelligence across purchasing, inventory, and accounting

Back Office is already leading this evolution, giving operators the tools to stay competitive regardless of market volatility.

Take Control of Your Food Costs Before They Control You

Food costs aren’t going to stabilize overnight, but operators don’t have to let volatility run the show.

With Back Office technology, restaurants gain the clarity, control, and consistency needed to protect profit margins without adding complexity to daily operations.

If you’re ready to move beyond spreadsheets and gut instinct and into smarter food cost management, now’s the time to take control of your bottom line.