If you work in restaurants long enough, you learn one thing pretty quickly: when the supply chain is off, everything feels harder. Prep takes longer. Orders get creative in the wrong way. Managers scramble. Margins take a hit.

Restaurant supply chain management sits behind almost every operational win or headache. It’s not flashy, and guests rarely see it, but it determines whether kitchens run smoothly or constantly feel like they’re playing catch-up.

This guide breaks down how the restaurant supply chain actually works, where operators tend to feel the most pressure, and what it takes to manage it in a way that supports consistency, cost control, and growth.

What Is Restaurant Supply Chain Management?

Restaurant supply chain management is everything that happens before food ever hits the plate. It covers how products are sourced, purchased, stored, delivered, and tracked across the operation.

That includes ingredients, beverages, packaging, smallwares, and the systems used to manage them. It also includes the decisions behind the scenes, like who you buy from, how often you order, how much inventory you carry, and how closely pricing is monitored.

A strong restaurant supply chain keeps those moving parts aligned. When it’s working well, teams spend less time reacting and more time running the business.

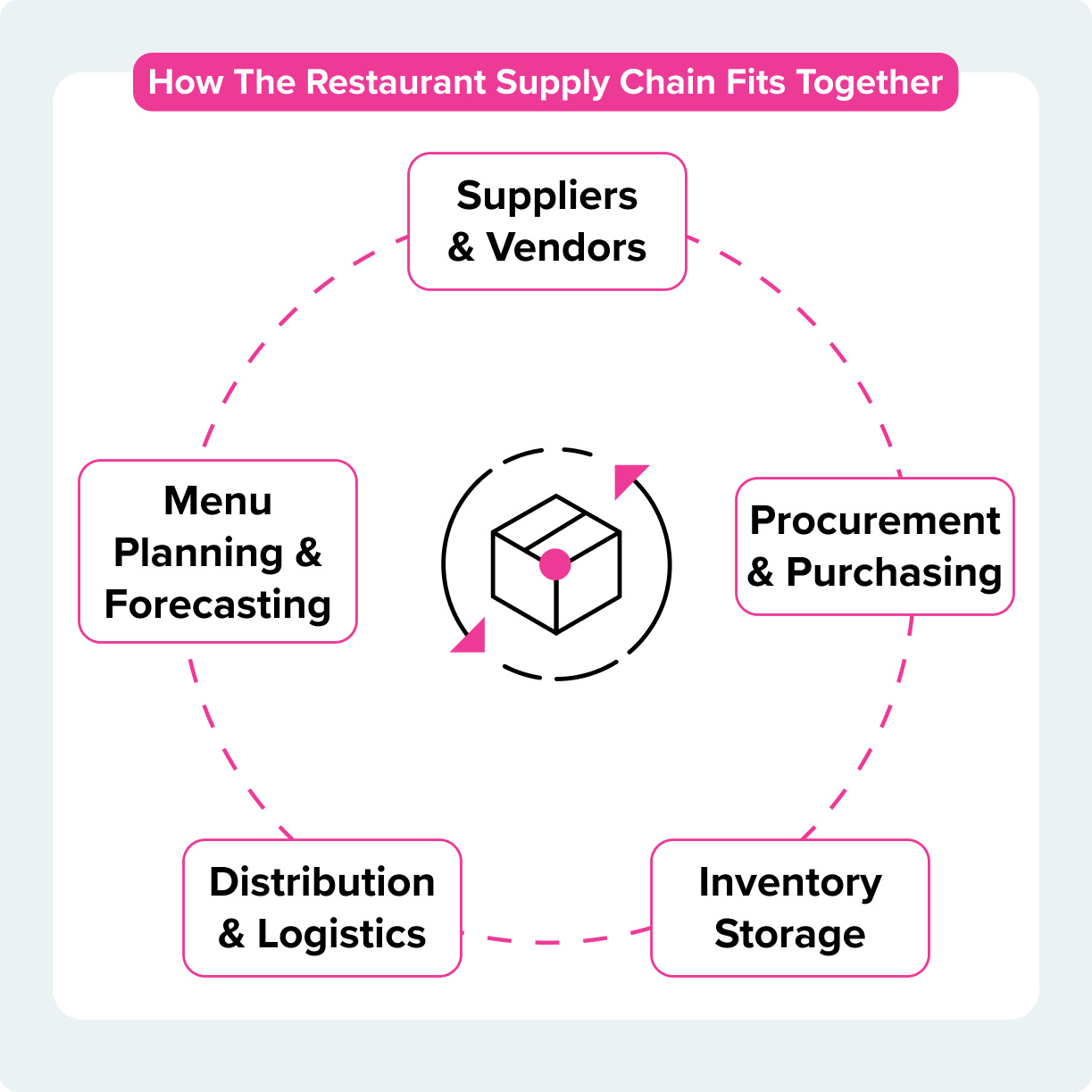

Core Components of the Restaurant Supply Chain

Every restaurant supply chain is made up of interconnected pieces. When one part slips, the impact usually shows up somewhere else, whether that’s food cost, labor stress, or a menu that suddenly feels harder to execute.

Understanding these core components makes it easier to spot where problems start and where small adjustments can make a big difference.

Supplier and Vendor Networks

Suppliers and distributors are the backbone of the restaurant supply chain. They influence pricing, product availability, quality consistency, and how quickly issues get resolved when something goes sideways.

Strong supplier relationships go well beyond price lists. In practice, they’re built on a few key factors:

- Reliable delivery and fill rates

- Clear communication when disruptions occur

- Consistent product specs and quality

- Willingness to problem-solve during shortages

When market conditions shift, those relationships often determine whether a restaurant adapts smoothly or scrambles to react.

Procurement and Purchasing Processes

Procurement is where restaurant supply chain strategy turns into daily action. It includes item selection, negotiated pricing, ordering habits, and how closely teams follow agreed-upon contracts.

Costs tend to go up slowly when the steps for buying things aren’t clear or consistent. Over time, this can lead to price differences, unnecessary substitutions, or locations buying things that aren’t on the approved list.

When procurement is standardized and well-managed, restaurants gain tighter spend control and fewer surprises on invoices.

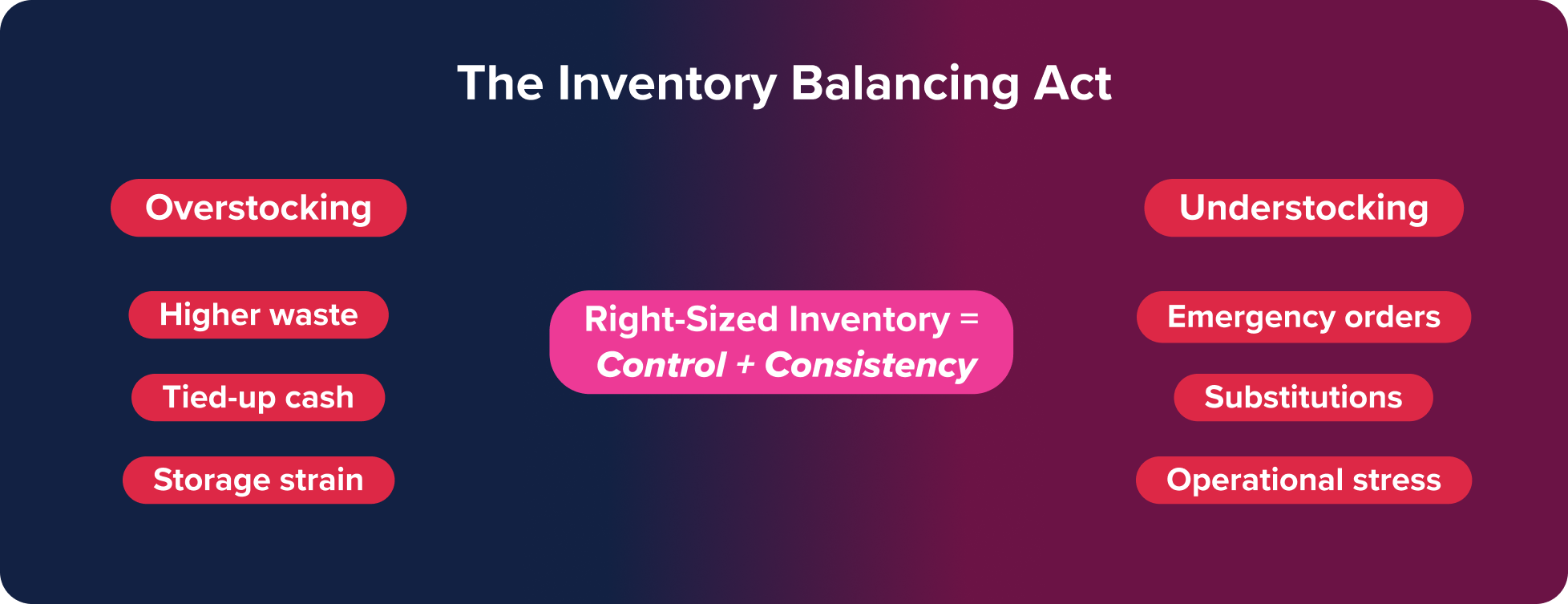

Inventory Storage and Handling

Inventory is one of the most common pressure points in the restaurant supply chain. Too much inventory ties up cash and increases waste. Too little leads to rushed orders, substitutions, and stressed teams.

Strong inventory practices usually come down to a few fundamentals:

- Accurate, regular inventory counts

- Proper storage and rotation

- Clear ownership and accountability

- Ordering based on actual usage, not habit

When inventory is managed intentionally, availability, freshness, and cost control stay in balance.

Distribution and Logistics

Distribution is where restaurant supply chain issues usually show themselves first. A truck shows up late. An item is shorted. Something arrives that technically matches the invoice but doesn’t work for tonight’s prep.

Those moments force managers to scramble. Prep plans change. Labor gets pulled in the wrong direction. Service feels harder than it should.

When logistics are reliable, none of that happens. Deliveries show up when expected, orders are complete, and kitchens can stay focused on execution instead of fixing problems they didn’t create.

Menu Planning and Demand Forecasting

Menus and the restaurant supply chain are tightly connected. Promotions, seasonal items, and menu changes all influence purchasing needs.

Better demand forecasting helps restaurants align ordering with real sales patterns, which reduces last-minute buying and unnecessary overstock. Over time, that alignment leads to more stable costs and smoother operations.

Why Restaurant Supply Chain Management Is Critical

The restaurant supply chain touches every part of the business. When it’s managed intentionally, it protects margins, supports consistency, and reduces daily stress for teams.

Cost Control and Margin Protection

Food and supply costs are among the largest line items on a restaurant P&L. Even small pricing inconsistencies or inefficient ordering habits can add up quickly.

Effective restaurant supply chain management helps operators:

- Catch pricing issues earlier

- Improve purchasing discipline

- Reduce unnecessary spend

- Protect margins without cutting quality

Those gains may seem incremental, but they compound over time.

Consistent Product Quality and Availability

Guests expect consistency. When the restaurant supply chain is reliable, kitchens can execute menus the same way every shift, every location.

Consistency builds trust with guests and reduces operational friction for teams, especially in multi-location environments.

Reducing Food Waste and Overstocking

Waste often starts with misaligned ordering. Overstocking leads to spoilage. Underordering leads to emergency buys.

A well-managed restaurant supply chain balances inventory levels so product is used when it should be, not tossed or rushed.

Operational Efficiency Across Locations

For multi-location restaurants, supply chain complexity grows fast. Standardized processes and shared visibility help leaders manage purchasing and inventory without micromanaging every unit.

Common Challenges in Restaurant Supply Chain Management

Even the best-managed restaurants have problems with their supply chains. The difference is how quickly they can spot problems and deal with them.

Supplier Reliability and Disruptions

Bad weather, not having enough workers, or problems with production can all affect how well a supplier does with little warning. Restaurants that rely too much on one source are usually the ones that have the most trouble.

Rising Ingredient and Transportation Costs

The prices of ingredients and shipping costs keep changing. Without being able to see trends, restaurants often wait until costs have already gone up before they act, which doesn’t leave much room for proactive changes.

Limited Visibility Into Spend and Inventory

It’s hard to know how much you really spend and use when systems aren’t connected. Limited visibility creates blind spots that slowly hurt profits over time.

Demand Forecasting Inaccuracies

Forecasting isn’t always right, but when there are big differences between what you expect and what you actually get, it can lead to waste, stockouts, and stress at work.

Managing Supply Chains Across Multiple Locations

As restaurants grow, they become less consistent. Different ways of ordering, different vendors, and different pricing structures can all make the restaurant supply chain less efficient.

Sustainability and Compliance Requirements

Expectations for sustainability and rules that businesses must follow are getting stricter. Managing the supply chain is even harder when you have to keep track of sourcing, handling, and compliance.

Best Practices for Effective Restaurant Supply Chain Management

There are proven ways to make the restaurant supply chain stronger, even though problems will always come up.

Build Strong Supplier Relationships

Long-term partnerships and open communication make things more reliable and clear, especially when things go wrong.

Standardize Purchasing and Procurement

Standardized purchasing helps cut down on differences, make it easier to follow the rules, and make it easier to keep an eye on things across locations.

Improve Inventory Accuracy and Controls

Regular counts, clear storage rules, and holding people accountable cut down on waste and help people make better ordering decisions.

Use Data to Forecast Demand More Accurately

Sales history, seasonality, and how well the menu does are all good signs for making better predictions.

Reduce Waste Through Better Planning

Aligning ordering, prep, and menu strategy keeps you from making too much food and having too much stock.

Diversify Suppliers to Reduce Risk

When something goes wrong in the restaurant supply chain, having multiple sources makes things more flexible.

Align Supply Chain Decisions With Menu Strategy

Menus should show what the supply chain can always and affordably support.

Train Teams on Supply Chain Processes

Teams can only follow clear processes if they know what they are and do them all the time.

Role of Technology in Restaurant Supply Chain Management

Technology is now a key part of how restaurants manage their supply chains. Connected systems help centralize purchasing information, make prices and inventory easier to see, and help you make better decisions.

Restaurants can stop reacting all the time and start planning ahead when they have better information.

Manage Restaurant Supply Chain With Buyers Edge Platform

Managing a restaurant supply chain doesn’t have to mean juggling spreadsheets, emails, and disconnected tools. A more connected approach brings purchasing, inventory, and data into one clearer view.

That clarity helps restaurants control costs, reduce waste, and operate with more confidence as they grow.

Ready to take a more connected approach to your restaurant supply chain? Click here to discover how Buyers Edge Platform helps restaurants gain visibility, control costs, and manage their supply chain with confidence.

FAQs

What are the biggest supply chain challenges for restaurants today?

Most restaurants are dealing with rising costs, supplier disruptions, limited visibility into spend, and unpredictable demand. These pressures make effective restaurant supply chain management essential.

How can restaurants reduce supply chain costs without sacrificing quality?

Consistency matters. Standardized purchasing, strong supplier relationships, and data-driven decisions help control costs while maintaining quality.

How does supply chain management affect food waste?

When ordering and forecasting are misaligned, waste follows. Better inventory controls and demand planning reduce spoilage and overproduction.

What technology helps improve restaurant supply chain visibility?

Technology that connects purchasing, inventory, and reporting provides clearer insight into how the restaurant supply chain is performing.

How can multi-location restaurants manage supply chains more effectively?

Standardized processes, centralized data, and consistent supplier strategies help multi-location restaurants maintain efficiency without losing flexibility.